AI Warehouse Management: Complete 2025 Guide

AI warehouses are processing 300% more orders with 50% fewer errors—here’s how.

The numbers don’t lie: the global AI in warehousing market is valued at $11.22 billion in 2024 and projected to grow at a CAGR of 26.1% from 2025 to 2030. Collaborating with 3PLs that invest in AI capabilities can unlock 75% faster processing and 25% productivity improvements.

What you’ll learn in 5 minutes:

- The 5 AI applications transforming warehousing

- Real ROI numbers from companies doing it right

- Your step-by-step implementation playbook

- How JenJan’s AI solutions drive fulfillment efficiency

The AI Revolution in Numbers

According to SuperAGI’s comprehensive 2025 analysis, the AI in warehousing sector shows explosive growth:

- Current market size: $11.22 billion in 2024

- Projected growth: 26.1% CAGR from 2025 to 2030

- Expected market size: Reaching $88.4 billion by 2033

- Business impact: Companies can expect reduction in inventory costs and improvement in forecast accuracy

Why the surge? The average warehouse experiences inventory inaccuracies of up to 30%, while labor shortages continue to plague the industry. AI provides the solution to both challenges simultaneously.

AI Applications Transforming Warehouses

1. Order Picking & Sorting

Technology Used: Robotic arms with computer vision, autonomous mobile robots (AMRs), AI-powered sorting systems

Real Example - Amazon:

- Challenge: Processing millions of daily orders with speed and accuracy across global fulfillment network

- **Solution: **Deployed 750,000+ robots including Sequoia system with integrated picking and sorting

- Results: 25% estimated productivity improvement, 75% faster inventory identification and storage, 25% reduction in order processing time

- Key Innovation: Ergonomic workstations where robots bring inventory to workers at optimal height, eliminating repetitive strain

- Source: Amazon

source: Amazon

2. Inventory Management

Technology Used: RFID technology, real-time tracking systems, augmented reality integration

Real Example - Walmart:

- Challenge: Apparel inventory accuracy difficulties due to high volume, fast turns and constant movement making it one of the most challenging retail categories to manage

- Solution: Deployed RFID tags that track location of every item in store or backroom, combined with AR technology through handheld devices

- Results: Product searches up to 75% faster, associates can instantly see item locations whether on sales floor, in backroom, or in transit

- Key Innovation: RFID + AR integration where associates scan product codes and AR overlays show exact location guidance, making inventory management significantly more efficient

3. Warehouse Optimization

Technology Used: Automated guided vehicles (AGVs), autonomous mobile robots (AMRs), AI-powered navigation and routing systems

Real Example - DHL:

- Challenge: Inefficient warehouse navigation and routing with workers spending excessive time walking long distances through complex warehouse layouts

- Solution: Deployed autonomous robotic systems that navigate warehouse spaces using AI-powered routing to optimize movement patterns

- Results: Slashed worker training times by up to 80%, teams spend less time on manual navigation and transportation tasks

- Key Innovation: Automated guided vehicles that navigate defined warehouse spaces using advanced routing algorithms, optimizing workflow patterns and reducing unnecessary movement throughout facilities

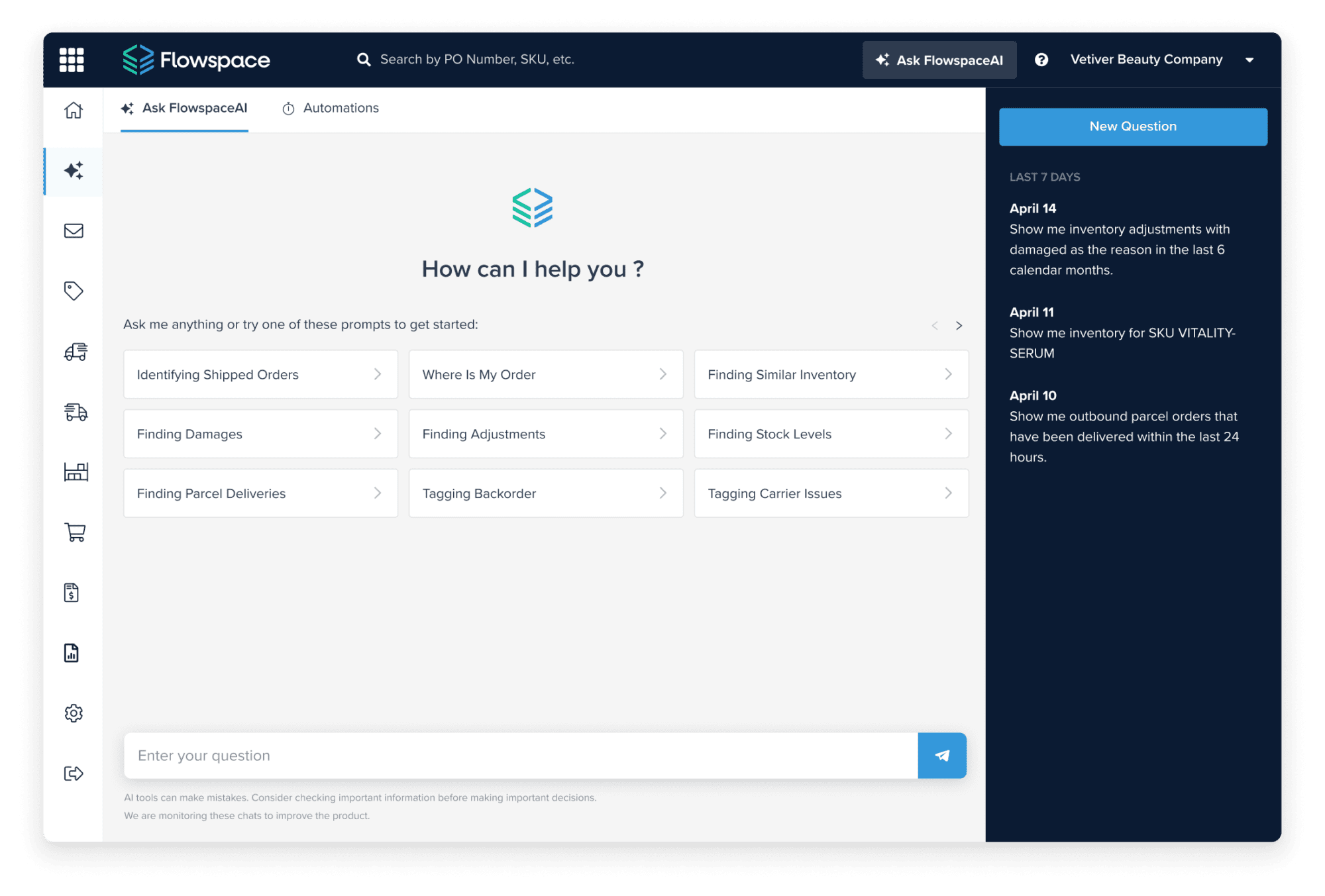

4. Fulfillment Status & Warehouse Tracking

Technology Used: AI chatbots integrated with WMS, real-time inventory tracking, automated status updates, natural language processing

Real Example - Walmart & DHL Integration:

- Challenge: Customers constantly inquire about order fulfillment status, warehouse location, shipping updates, and inventory availability, overwhelming customer service teams

- Solution: AI-powered chatbots integrated with warehouse management systems provide real-time updates on order processing, warehouse picking status, inventory levels, and shipping notifications automatically

- Results: Walmart’s AI chatbots provide real-time inventory status and order fulfillment updates, reducing customer service workload by 60-70%; DHL’s AI systems handle shipping inquiries efficiently while providing 95% prediction accuracy for delivery updates

- Key Innovation: Smart integration between AI customer service and warehouse operations - chatbots can check if orders are “picked,” “packed,” “shipped,” or “in transit” by connecting directly to WMS data, providing customers instant fulfillment visibility without human intervention

source: Flowspace

Your 3PL Selection Roadmap

Phase 1: Assessment (Month 1)

✅ Audit Your Current 3PL Capabilities

- Evaluate your existing fulfillment provider’s AI integration capabilities

- Identify pain points in order processing, inventory visibility, and customer communication

- Calculate costs of manual processes and customer service bottlenecks

Phase 2: 3PL AI Evaluation (Months 2-3)

✅ Partner with AI-Enabled 3PL Providers

- Look for 3PLs with integrated AI warehouse management systems

- Prioritize providers offering real-time inventory tracking and automated customer updates

- Evaluate 3PL partners with AI-powered demand forecasting and route optimization

Phase 3: AI Integration & Scaling (Months 4-12)

✅ Leverage Your 3PL’s AI Infrastructure

- Implement AI-powered order status tracking through your 3PL’s systems

- Utilize 3PL’s predictive analytics for inventory planning and demand forecasting

- Scale operations using your 3PL’s automated fulfillment and customer communication tools

JENJAN: AI-Powered Cross-Border Fulfillment

At JenJan, we’re implementing cutting-edge AI tools to revolutionize fulfillment efficiency and inventory management for cross-border operations between Asia and North America.

1. AI-Enhanced Fulfillment:

- Smart Inventory Allocation: AI algorithms predict demand patterns across Asia-US corridors, optimizing stock placement

- Automated Order Routing: Machine learning determines the most efficient fulfillment path for each order

2. AI-Assisted Inventory Management:

- Predictive Restocking: Forecasting algorithms prevent stockouts while minimizing overstock across satellite warehouses

- Cross-Border Compliance: AI ensures inventory meets regulatory requirements for both Taiwan and US markets

- Conversational Analytics: AI-powered chat interface allows instant queries like “Show me order status for #TW2024-001” or “What’s the average processing time for electronics shipments this month?” providing immediate data insights without technical training

Take Action:

Questions about warehouse automation, inventory management, or Taiwan-US cross-border fulfillment? Contact our experts for personalized guidance.